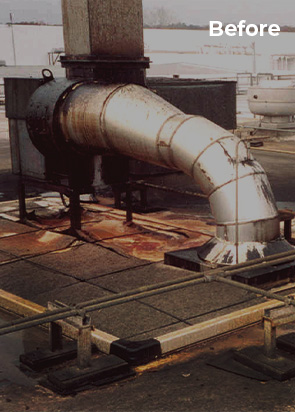

Demister Filtration Systems

To eliminate oil and grease buildup on your roof, our Demister Systems use a three-stage process for filtration including velocity reduction and centrifugal separation, water spray scrubbing and demister pad filtration. First, the air is discharged tangentially down into a larger vessel resulting in lower air speeds, which cause the larger particles to fall out of the exhaust air. The exhaust air is then forced to turn up through the demister vessel, which causes more grease to fall out against the vessel sides and bottom. Second, we use water spray showers in the demister vessel body to “scrub” the airflow of grease and oil. Finally, we have incorporated a specially designed demister filter to capture as much of the remaining grease and oil as possible. There are no moving components in the demister vessel and the filtered material is continuously washed from the vessel by the water flow. These units are self-cleaning and have no moving parts in the air stream.

Specifications

1Weather Enclosure

- Encloses the motor and blower assembly to protect from the weather elements, ships assembled with the blower

- Solid floor with angle base, carbon steel construction with air inlet top

- Access doors for electrical maintenance and manual damper adjustment

- Acoustic lining available to reduce noise

2Pressure Blower

- Located on the roof for noise reduction and floor space savings

- The blower will never come in contact with the exhaust stream, so it is more reliable and typically will not have to be cleaned

3Venturi Exhauster

Superior design and precision manufacturing make the Quickdraft Venturi Exhauster the most efficient, consistent and reliable method for maintaining process exhaust requirements.

- No obstructions to the exhaust flow and all moving parts are external to the air stream

- Little or no maintenance

- Consistent, dependable exhaust performance

- Duct can be thoroughly cleaned without harming the blower

- Designed for 24/7 operation

- Long service life

4Exhaust Filtration

Demister Filter

• A three-stage process is used to remove grease, oil and particulate from the exhaust air stream

– Knockdown and Velocity Reduction are used to slow the exhaust air stream and allow larger particles to fall out of the exhaust flow

– Water spray showers located at optimum locations are used to “scrub” the airflow of grease, oil and particulates

– A specially designed series of Demister filter pads capture as much of the remaining grease, oil and particulates as possible.

• Filters are heat-resistant, woven-poly material several inches thick

• Frames allow the cleaning crew to easily remove and reinstall for cleaning

• Filters are made from various materials based on the maximum temperature of the exhaust

5Water Recirculation

- Significantly reduces water consumption in the Demister

- Provides required flow for maximum filtration efficiency

- Includes pressure regulator and gauge for flow adjustment

- Automatically skims grease to separate drain

- Automatically introduces make-up water to the sump

- Stainless steel construction with a washdown duty motor

6Oven/Fryer/Microwave

Quickdraft works closely with many manufacturers who supply ovens, fryers, blanchers, washers, mixers, etc., for the food industry. Our systems are designed for the manufacturer’s recommended exhaust flow and exhaust temperature for your process.

Features and Benefits

- No moving components, easy to maintain

- Three-stage filtration:

- – Centrifugal

- – Wet scrubber

- – Demister pad filter

- 100% efficient for particles 5 micron or greater

- 96% efficient for 3 micron particulate

- 70% efficient for 2 micron particulate

- Higher efficiencies are available

- All stainless-steel construction

Extend the useful life of your roof by keeping it clean

Applications

Benefits

- Filter grease, oil and other contaminants from exhaust air stream

- Eliminate grease and oil accumulation on roof

- Exhaust volumes to 40,000 CFM

- Constructed from 304, 309 or 316 stainless steel

- Weather enclosure, storm shield, silencing equipment and other accessories available

Venturi-Powered Systems

Explore the most efficient method for conveying material without moving parts.

Learn More

Engineering and Manufacturing

Learn about our engineering design, fabrication, assembly and finishing capabilities.

Learn More